Copyright belongs to the author. For commercial reprints, please contact the author for authorization, and for non-commercial reprints, please indicate the source.

Every day we throw away a lot of packaging waste, some recyclable, some non-recyclable, and more between recyclable and non-recyclable.

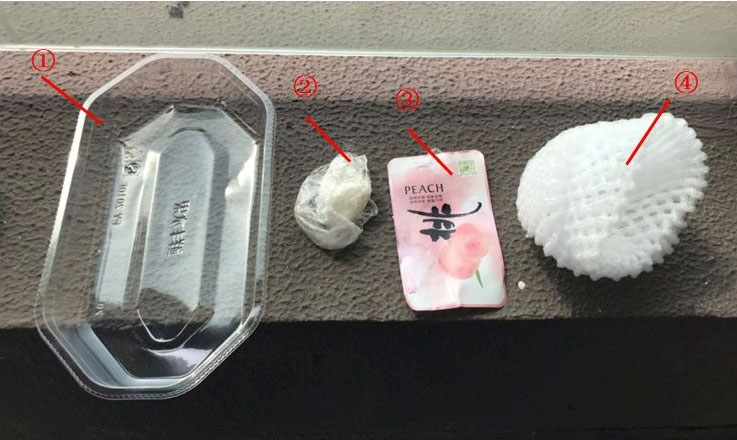

Taking the outer packaging of this peach as an example (see Figures 1 and 2), four different packaging wastes are generated after disposal:

1-PET cover;

2-PE plastic wrap;

3-Laminated self-adhesive stickers;

4-PE foam cotton;

The original four packaging materials are all recyclable, but the 3-sticker paper is stuck on the plastic wrap, and after tearing off, the plastic wrap is stuck on the back of the paper, which increases the difficulty of back-end processing and reduces the recyclability of the material.

Can the four types of packaging waste be reduced to three? Or both?

If using cardboard or PE film printing instead of paper printing?

Some people may propose to reduce production efficiency, or increase front-end material costs.

Another example is a jewelry packaging box (see Figure 3 and Figure 4), the internal structure is as follows:

1-Inner lining, white paper on gray background, cotton flannel, adhesive bonding;

2- Lower cover, from outside to inside: special white cardboard, wood, white paper on gray background, cotton flannel, bonded with a lot of adhesives;

3-Top cover, from outside to inside: special white cardboard, wood, white paper on grey background, cotton flannel, bonded with a lot of adhesive.

I tried to split this box, and it took an hour to completely peel off every material.

Materials that can be recycled become difficult to recycle in our complex processes.

In the growing career of the packaging industry, the disposal of packaging waste has always been a neglected link in the design process. Is there a more reasonable way to measure the rationality of packaging design choices?

Take peach packaging as an example,

1-PET cover, assumed cost a0, effective recovery cost a1, waste disposal cost a2;

2-PE plastic wrap, assumed cost b0, effective recovery cost b1, garbage disposal cost b2;

3- Laminated self-adhesive stickers, assumed cost c0; effective recovery cost c1, garbage disposal cost c2;

4-PE foamed cotton, assumed cost d0; effective recovery cost d1, waste disposal cost d2;

In the current packaging design cost accounting, the total packaging material cost = a0+b0+c0+d0;

And when we consider packaging recycling profits and waste disposal costs,

Total packaging material cost = a0+b0+c0+d0-a1-b1-c1-d1+a2+b2+c2+d2;

In the current packaging design cost accounting, the total packaging material cost = a0+b0+c0+d0;

When the total cost of product packaging not only considers the cost of existing consumables, but also considers the recyclable value of back-end materials, so as to find a way to optimize the total cost of packaging materials, minimize pollution to the natural environment, and maximize packaging materials Such green packaging design is worthy of our discussion and research when it comes to recycling packaging solutions

Post time: Oct-31-2022